M23

Landscapers Dream Machine

Landscapers dream machine

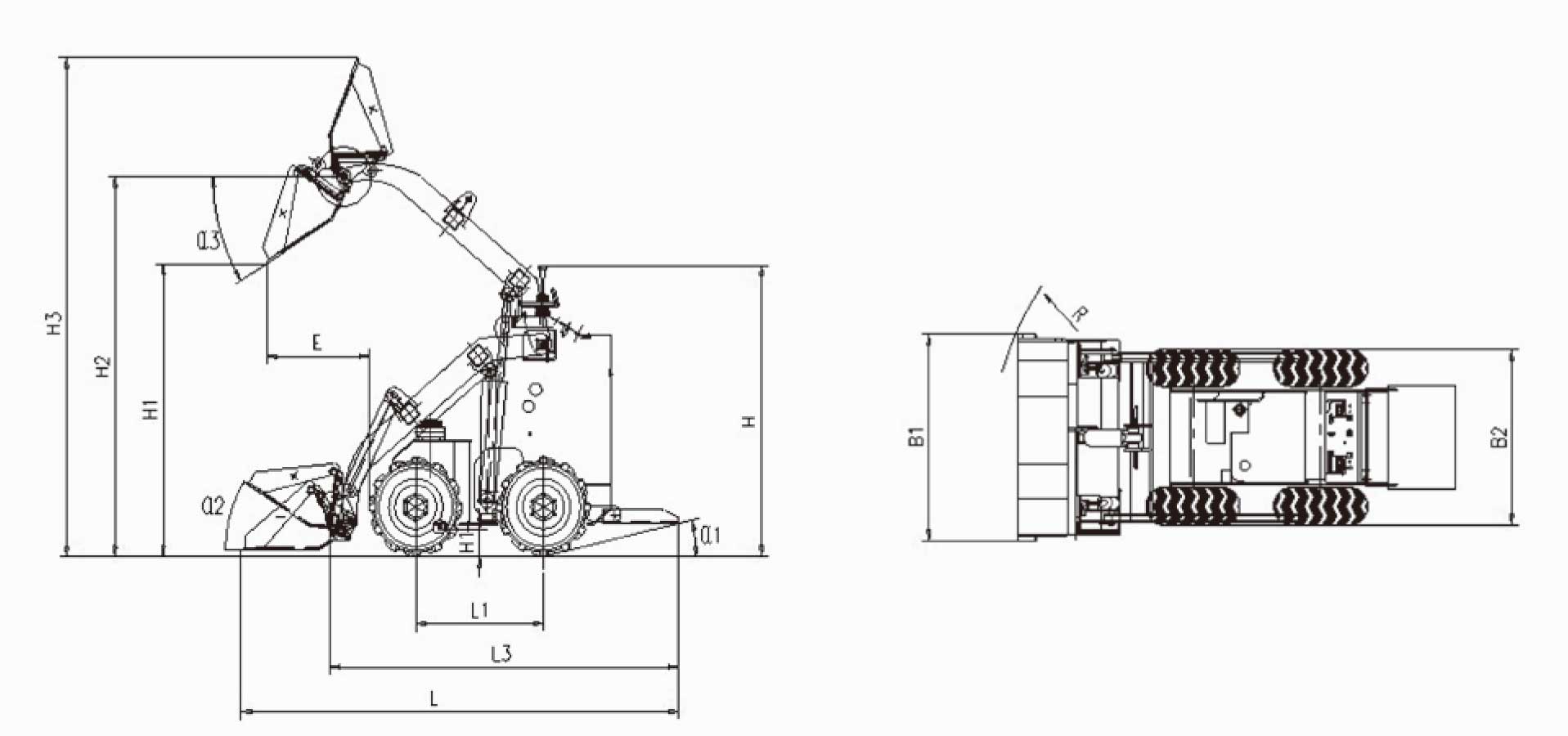

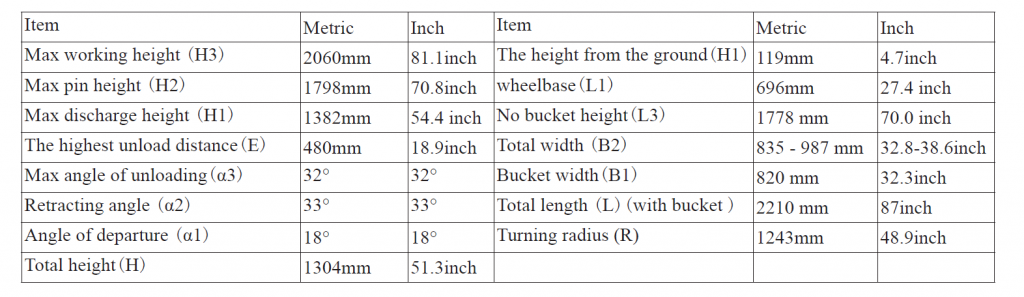

The M23 is our most compact mini digger and depending on tyres sizes chosen can be as little as only 835mm wide. With standard Chevron tyres offering more grip in wet conditions it is still only 987mm in width.

With 23HP it has all the muscle you need to get the job done increasing your work output and decreasing the time it takes to do it all, meaning more time for you! Popular with landscapers, fencing contractors, builders & DIY. Buy with confidence - Australia’s best value compact loader.

Product features

· Full 4 way joystick left-hand,allowing a separate right-hand control for the bucket, allowing lift & tilt on the run.

· 4 hydraulic motors are used to drive each wheel independently. 4 motors made in USA.

· 23HP U.S BRIGGS & STRATTON petrol engine. Made in Japan.

· Italian brand valve

· Operating weight: 807KG

· Dimension(mm)(no bucket)(L*W*H): 1778mm*987mm *1304mm. Change of tires types, width can be as little as 851mm, machine can enter into narrower space to work.

· Machines feature an ergonomic hand grip layout

· It is the same powerful machine as our bigger machine yet in a more compact design allowing it to enter narrower and confined spaces.

Facts about M23

Specially designed motor support sleeve

Common to mini diggers on the market now with a four hydraulic motor design is that the motor is mounted directly on the side plate of the rack, with the motor output shaft cantilever mounts over the tyres. The motor output shaft is then unsupported and operational forces could reduce the service life of the motor. Also motor maintenance and disassembly must be done from the inside of the rack and it is a complex task.

However, the Meerkat mini digger's four-motor-driving system is connected to the frame through a specially designed motor support sleeve and the forces transmitted to the motor output shaft have been reduced by more than 50%, significantly improving the service life of the motor. At the same time, the motor can be easily removed by loosening the bolts of the externally mounted motor support sleeve, reducing maintenance downtime and labour costs if required.

Mini diggers designed to work in narrow spaces for the professional & DIY

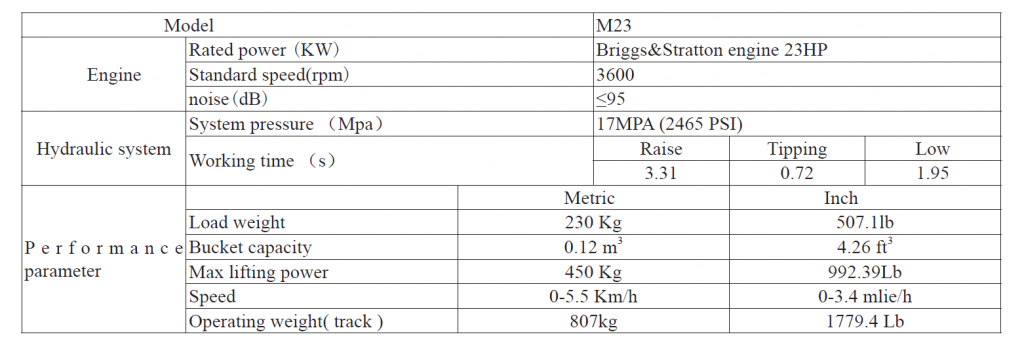

M23 main specification

Main performance parameter